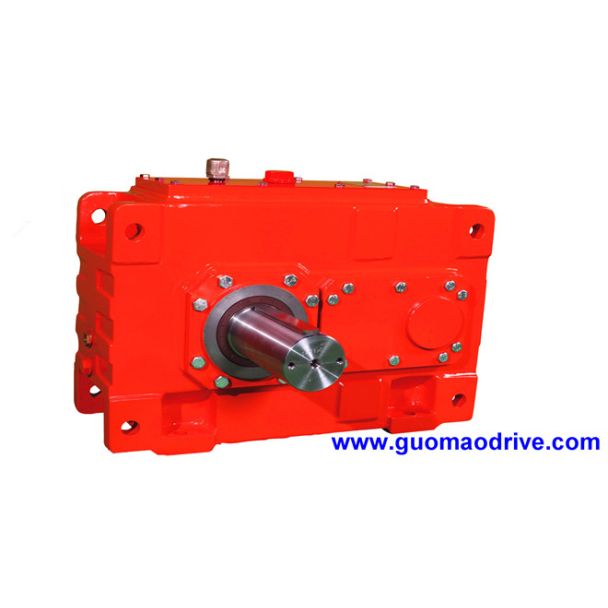

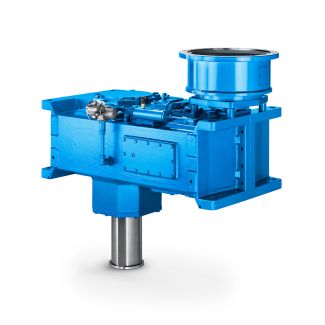

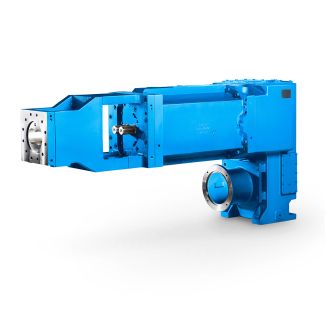

H2-SH7-B acoplamento flender Helical gear reducer H2

In stock

SKU

H2-SH7-B

$10,821.43

Flender/Flender Gear Units/Helical gear reducer H2

), considered percent- age of grain separated through concave ( Es), which is dened as, Es/H1Ws WA/H1 ( where Wsrepresents grain quantity collected after ow through the concave and, therefore, includes unthreshed grain and blown grain. So, for given crop

grain quantity collected after ow through the concave and, therefore, includes unthreshed grain and blown grain. So, for given crop  condition and thresherdesign parameters, system variables (Wieneke called them adjustments and operational Harvesting and Threshing 9 Fig. 1 General functional

condition and thresherdesign parameters, system variables (Wieneke called them adjustments and operational Harvesting and Threshing 9 Fig. 1 General functional  characteristics of rasp-bar cylinder and open concave: , unthreshed grain loss; , grain damage; , percentage grain separated through concave.

characteristics of rasp-bar cylinder and open concave: , unthreshed grain loss; , grain damage; , percentage grain separated through concave.  (From Ref. 6.) parameters) need to be negotiated to obtain maximum grain separation ( Es), minimum grain damage ( Ed), and percentage grain unthreshed ( Eu). In general, for threshing crop with low moisture content, increased peripheral velocity and decreased concave clear-ance will result in thoroughness of threshing that has higher values of , and Et, and Ed, and lower values of Euwill be observed at reduced feed rate. Many researchers have evaluated the performance of threshers for wide range of cropcylindersystem variables. The optimum and near optimum range of cylindercon- cave parameters for cereal and pulse crops are summarized in Table 7. It is apparent thatthere is no specic cylinderconcave conguration that can be recommended for crop forthe best threshing effectiveness. Conversely, for the same cylinderconcave conguration,more than one crop can be effectively threshed following necessary adjustments withinthe threshing system. Therefore, for thresher, proper adjustments of peripheral velocity, concave clearance, and number of rows of threshing elements will be necessary to thresh wide variety of dried crops. In evaluating thresher, energy input and peak powerrequirements are given less weight than its characteristic performance for obtaining amaximum quantity of sound clean grains or seeds from cereal and pulse crops. 3.6 Grain or Seed Separation Separating sound grain or seed from chaff, broken

(From Ref. 6.) parameters) need to be negotiated to obtain maximum grain separation ( Es), minimum grain damage ( Ed), and percentage grain unthreshed ( Eu). In general, for threshing crop with low moisture content, increased peripheral velocity and decreased concave clear-ance will result in thoroughness of threshing that has higher values of , and Et, and Ed, and lower values of Euwill be observed at reduced feed rate. Many researchers have evaluated the performance of threshers for wide range of cropcylindersystem variables. The optimum and near optimum range of cylindercon- cave parameters for cereal and pulse crops are summarized in Table 7. It is apparent thatthere is no specic cylinderconcave conguration that can be recommended for crop forthe best threshing effectiveness. Conversely, for the same cylinderconcave conguration,more than one crop can be effectively threshed following necessary adjustments withinthe threshing system. Therefore, for thresher, proper adjustments of peripheral velocity, concave clearance, and number of rows of threshing elements will be necessary to thresh wide variety of dried crops. In evaluating thresher, energy input and peak powerrequirements are given less weight than its characteristic performance for obtaining amaximum quantity of sound clean grains or seeds from cereal and pulse crops. 3.6 Grain or Seed Separation Separating sound grain or seed from chaff, broken| Model Type | Helical gear reducer H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 505.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 20300 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Ibérica S.A. |

| Country of Manufacture | Cambodia |

| Data Sheet & Drawings | H2-SH7-B acoplamento flender Helical gear reducer H2 |