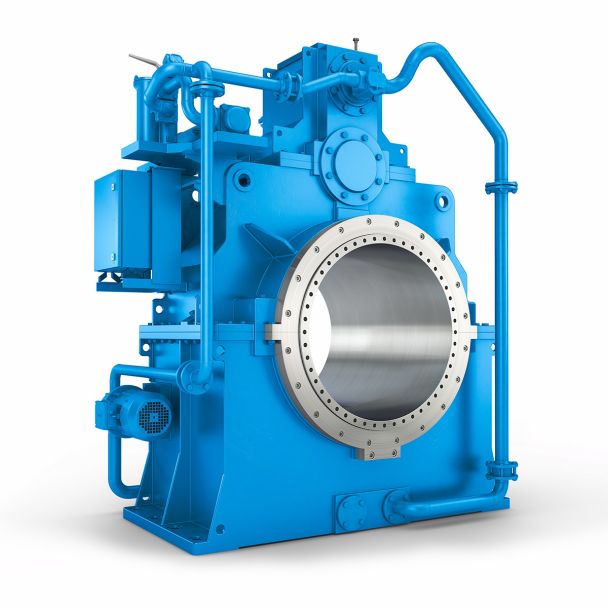

H2-FH19-B flender gears Helical speed reducers H2

In stock

SKU

H2-FH19-B

$141,428.57

Flender/Flender Gear Units/Helical speed reducers H2

ays Material ropeways 1.3 1.4 To-and-fro system aerial ropeways 1.6 1.8 -bar lifts 1.3 1.4 Continuous ropeways 1.4 1.6 Cement industry Concrete mixers 1.5 1.5 Breakers 1.2 1.4 Rotary furnaces 2.0 2.0 Separators 1.6 1.6 Roll crushers 2.0 Flender GmbH

industry Concrete mixers 1.5 1.5 Breakers 1.2 1.4 Rotary furnaces 2.0 2.0 Separators 1.6 1.6 Roll crushers 2.0 Flender GmbH  2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 3/1 Flender MD 2.1 2 3Design of the gear units Guidelines for

2NER GROUP CO.,LIMITED Germany sogears HB series gearbox 3/1 Flender MD 2.1 2 3Design of the gear units Guidelines for  selection Service factors Overview (continued) Thermal factor Kth Note: The listed load parameters are empirical values. Prerequi- site for their

selection Service factors Overview (continued) Thermal factor Kth Note: The listed load parameters are empirical values. Prerequi- site for their  application is that the machinery and equipment mentioned correspond to generally accepted design and load specifications. In case of deviations from standard conditions, please contact us. For driven machines which are not listed in this table, please refer to us.Driven machines Kth Waste water Thickeners (central drive) 1 Filter presses 0.8 Flocculation apparatus 0.8 Aerators 1 Raking equipment 0.8 Combined longitudinal and rotary rakes 0.8 Pre-thickeners 0.8 Water screw pumps 0.8 Water turbines 0.8 Pumps Centrifugal pumps 1 Displacement pumps -1 1 - > 1 piston 1 Excavators Bucket conveyors 0.8 Dumping devices 0.8 Caterpillars 0.8 Bucket wheels - as pick-up 0.8 - for primitive material 0.8 Cutter heads 0.8 Swing gears 0.8 Plate bending machines 0.8 Chemical industry 0.9 Dough mills 0.8 Rubber calenders 0.8 Cooling drums 0.8 Mixers for - uniform media 0.8 - non-uniform media 0.8 Agitators for/media with - uniform density 0.8 - non-uniform density 0.8 - non-uniform gas absorption 0.8 Toasters 0.8 Centrifuges 0.8 Metal working mills Plate tilters 0.8 Ingot pushers 0.8 Winding machines 0.8 Cooling bed transfer frames 0.8 Roller straighteners 0.8 Roller tables - continuous 0.8 - intermittent 0.8 Reversing tube mills 0.8 Shears - Continuous cut 0.8 - Crank type 0.8 Continuous casting drivers 0.8 Rolls - Reversing blooming mills 0.8 - Reversing slabbing mills 0.8 - Reversing wire mills 0.8

application is that the machinery and equipment mentioned correspond to generally accepted design and load specifications. In case of deviations from standard conditions, please contact us. For driven machines which are not listed in this table, please refer to us.Driven machines Kth Waste water Thickeners (central drive) 1 Filter presses 0.8 Flocculation apparatus 0.8 Aerators 1 Raking equipment 0.8 Combined longitudinal and rotary rakes 0.8 Pre-thickeners 0.8 Water screw pumps 0.8 Water turbines 0.8 Pumps Centrifugal pumps 1 Displacement pumps -1 1 - > 1 piston 1 Excavators Bucket conveyors 0.8 Dumping devices 0.8 Caterpillars 0.8 Bucket wheels - as pick-up 0.8 - for primitive material 0.8 Cutter heads 0.8 Swing gears 0.8 Plate bending machines 0.8 Chemical industry 0.9 Dough mills 0.8 Rubber calenders 0.8 Cooling drums 0.8 Mixers for - uniform media 0.8 - non-uniform media 0.8 Agitators for/media with - uniform density 0.8 - non-uniform density 0.8 - non-uniform gas absorption 0.8 Toasters 0.8 Centrifuges 0.8 Metal working mills Plate tilters 0.8 Ingot pushers 0.8 Winding machines 0.8 Cooling bed transfer frames 0.8 Roller straighteners 0.8 Roller tables - continuous 0.8 - intermittent 0.8 Reversing tube mills 0.8 Shears - Continuous cut 0.8 - Crank type 0.8 Continuous casting drivers 0.8 Rolls - Reversing blooming mills 0.8 - Reversing slabbing mills 0.8 - Reversing wire mills 0.8| Model Type | Helical speed reducers H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 6600.000000 |

| Ratio Range | 1 : 6.3…20 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 292000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender de Mexico, S.A. de C.V. |

| Country of Manufacture | Albania |

| Data Sheet & Drawings | H2-FH19-B flender gears Helical speed reducers H2 |