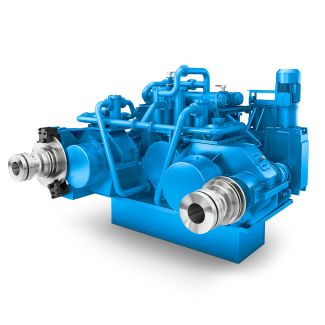

flender gearbox backstop H2-DV-7-A Helical gear unit H2

In stock

SKU

H2-DV-7-A

$10,821.43

Flender/Flender Gear Units/Helical gear unit H2

als, West Germany and Italy, November-December 1. 6 Transcript, pp. 4-4. training, just-in-time scheduling, and statistical process control techniques were suggested, as was the importance of demonstrated commitment to quality concepts. In connection with this, manufacturers were urged to continually

suggested, as was the importance of demonstrated commitment to quality concepts. In connection with this, manufacturers were urged to continually  update their equipment, developing high tech manufacturing capacity to improve efficiency and reduce costs. Delivery time and product availability demand

update their equipment, developing high tech manufacturing capacity to improve efficiency and reduce costs. Delivery time and product availability demand  attention. According to distributors, current lead times are unacceptable; complete product lines, they stated, should be available with shorter delivery

attention. According to distributors, current lead times are unacceptable; complete product lines, they stated, should be available with shorter delivery  lead times. 5 Major foreign manufacturers have supplanted domestic producers in some gear categories by supplying technologically advanced gear products at lower cost. Independent .. gear distributors indicated that imports were able to gain foothold in the .. market because of the appearance of multibranch national distributor chains that purchase gears in bulk at prices well below those available to independent distributors. In order to remain competitive with the multinational chains, independents began to import price-competitive gears from Western Europe and Japan. With the advent of the chains, according to the independent distributors, the bond of loyalty between domestic producers and independents was also lessened because of .. producers' fears of increased import competition. 5 .. distributors believe that if .. gear manufacturers are going to retain their market share, they must develop products that are competitive in terms of technology and price, must increase communication with domestic customers, and must develop export marketing networks. Distributors suggested that manufacturers should also take steps, such as evaluating production costs and design factors, to reduce prices. Increased research and product development were recommended, focusing in particular on improved horsepower and torque ratings per

lead times. 5 Major foreign manufacturers have supplanted domestic producers in some gear categories by supplying technologically advanced gear products at lower cost. Independent .. gear distributors indicated that imports were able to gain foothold in the .. market because of the appearance of multibranch national distributor chains that purchase gears in bulk at prices well below those available to independent distributors. In order to remain competitive with the multinational chains, independents began to import price-competitive gears from Western Europe and Japan. With the advent of the chains, according to the independent distributors, the bond of loyalty between domestic producers and independents was also lessened because of .. producers' fears of increased import competition. 5 .. distributors believe that if .. gear manufacturers are going to retain their market share, they must develop products that are competitive in terms of technology and price, must increase communication with domestic customers, and must develop export marketing networks. Distributors suggested that manufacturers should also take steps, such as evaluating production costs and design factors, to reduce prices. Increased research and product development were recommended, focusing in particular on improved horsepower and torque ratings per| Model Type | Helical gear unit H2 |

|---|---|

| Gear Type | Helical Gear |

| Weight (kg) | 505.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 20300 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | A. Fried. Flender AG |

| Country of Manufacture | Solomon Islands |

| Data Sheet & Drawings | flender gearbox backstop H2-DV-7-A Helical gear unit H2 |