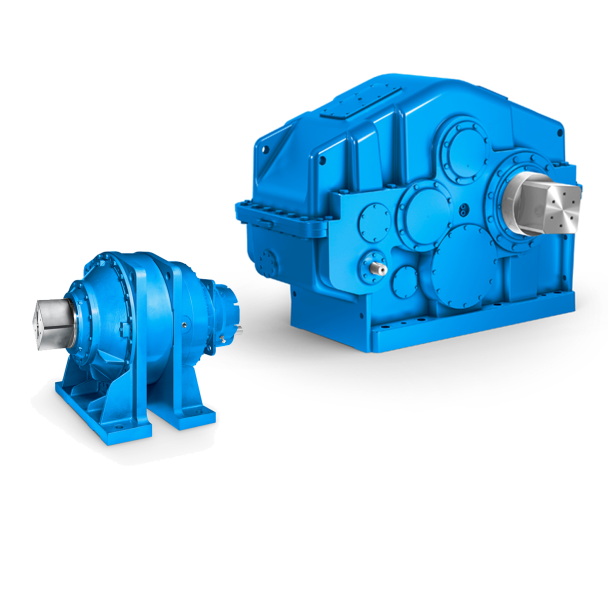

B4KH-23-C ted pump and oilwater cooler b Plate heat exchange Bevel-helical gearboxes B4

In stock

SKU

B4KH-23-C

$257,142.86

Flender/Flender Gear Units/Bevel-helical gearboxes B4

ut not limited to auxiliaries, Machine monitorin , Plant Electrics, Data acquisition and Historian, Sequence of event recording, Pe rformance calculation, Man machine interface and data transfer to the oth er Control System and Plant Wide Network for MIS integration.

calculation, Man machine interface and data transfer to the oth er Control System and Plant Wide Network for MIS integration.  The proposed PLC shall be able to control and monitor all elect rical system / equipment with auto plant star

The proposed PLC shall be able to control and monitor all elect rical system / equipment with auto plant star  -up, auto synchronization and shutdown with controller loading < 6%. Control System The control system along with its measurement system

-up, auto synchronization and shutdown with controller loading < 6%. Control System The control system along with its measurement system  shall perf orm functions of closed loop control, sequence cont rol, interlock & protection of Compressors and auxiliaries in all regimes of unit operation. The control syste shall consist of the following basic system: . Natural Gas Compressor Control & Protection System Ii. Open Loop Control System (OLCS) . Closed Loop Control System (CLCS) The measurement and control system shall perform the functions of signal acquisition, conditioning and signal distribution of various ty pes of inputs / outputs like analog (4-2 mA DC, thermocouple, RTD), binary, pu lse etc. Separate & dedicated measurement system shall be provided for ach of the system indicated above. Human Machine Interface System (HMI) 1 of 1 INDRADHANUSH GAS GRID LIMITED TECHNICAL SPECIFICATION FOR NATURAL GAS COMPRESSOR STATION FOR NORTH EAST GAS GRID PIPELINE PROJECT TS NO.: MEC//2UU/0/2/0 Control & Instru mentation (&) Chapter-0.0 2, MECON Limited, All Right Reserved Page 8 of 1 The HMI System shall perform con trol, monitoring and operation of TB and auxiliaries in all regimes of unit operation, interacting with the control system. For this, HMI system shall primarily perform following functions. . Operator interface for control system. ii. Plant supervisory functions like displays, alarm monitoring & reporting (reports & logs, calculations, trend recording, historical and long term data storage & retrieval, etc.). System Progra

shall perf orm functions of closed loop control, sequence cont rol, interlock & protection of Compressors and auxiliaries in all regimes of unit operation. The control syste shall consist of the following basic system: . Natural Gas Compressor Control & Protection System Ii. Open Loop Control System (OLCS) . Closed Loop Control System (CLCS) The measurement and control system shall perform the functions of signal acquisition, conditioning and signal distribution of various ty pes of inputs / outputs like analog (4-2 mA DC, thermocouple, RTD), binary, pu lse etc. Separate & dedicated measurement system shall be provided for ach of the system indicated above. Human Machine Interface System (HMI) 1 of 1 INDRADHANUSH GAS GRID LIMITED TECHNICAL SPECIFICATION FOR NATURAL GAS COMPRESSOR STATION FOR NORTH EAST GAS GRID PIPELINE PROJECT TS NO.: MEC//2UU/0/2/0 Control & Instru mentation (&) Chapter-0.0 2, MECON Limited, All Right Reserved Page 8 of 1 The HMI System shall perform con trol, monitoring and operation of TB and auxiliaries in all regimes of unit operation, interacting with the control system. For this, HMI system shall primarily perform following functions. . Operator interface for control system. ii. Plant supervisory functions like displays, alarm monitoring & reporting (reports & logs, calculations, trend recording, historical and long term data storage & retrieval, etc.). System Progra| Model Type | Bevel-helical gearboxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 12000.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 640000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | A. Friedr. Flender GmbH |

| Country of Manufacture | North Macedonia |

| Data Sheet & Drawings | B4KH-23-C ted pump and oilwater cooler b Plate heat exchange Bevel-helical gearboxes B4 |