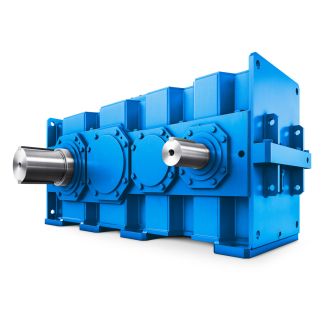

B4-SH-9-D ion LP B V Forced lubrication by motor pum Bevel-helical gearbox B4

In stock

SKU

B4-SH-9-D

$19,071.43

Flender/Flender Gear Units/Bevel-helical gearbox B4

soft1 structure porous structureV bond vitried porosity high porosity 6.5.5 Grinding Technology 6.5.5.1 Calculating the Specic Material Removal Rate The specic material removal rate is an important variable in the analysis of grinding process. It species the volume of stock

specic material removal rate is an important variable in the analysis of grinding process. It species the volume of stock  removed per unit time andmillimetre of contact width, making it possible to compare different grinding methods and processes. The volume

removed per unit time andmillimetre of contact width, making it possible to compare different grinding methods and processes. The volume  of stock removed wis measure of the volume of metal removed from the work piece by grinding, and is calculated

of stock removed wis measure of the volume of metal removed from the work piece by grinding, and is calculated  from the area of the tooth ankand the removed grinding allowance. When compared to standard grindingprocess like at grinding, the inuencing variables for the specic material removalrate in bevel gear grinding process, such as the feed eand the grinding wheel width , are not constant. More analytically, the differences in feed along the proleheight and the changing contact line along the face width must be accounted for. This results in specic material removal rate which can only be calculated point- by-point and is represented over the whole tooth area. Calculations of this kind forcylindrical gears are performed by [ KLOC0 ]. In simplied approach, for spiral bevel gears, an attempt can be made to approximate conditions to those in standard grinding process (Table 6..6.5 Grinding Spiral Bevel Gears 2 6.5.5.2 Process Parameters Generating Speed, Radial Feed These variables determine the specic material removal rate for the generating and plunge cutting processes. When tooth ank (slot) is being generated, the cradle and the work piece perform combined motion whose result is an octoid tooth ank prole. Therotational speed of the cradle is called the generating speed whose value is deter-mined by the module of the gear and feed per cycle (guide value: 5 /C1per second). The plunge feed denes the speed at which the tool plunges, into the tooth slot, along its axial direction and is determined by the module of the gear and the depthfeed per cycle

from the area of the tooth ankand the removed grinding allowance. When compared to standard grindingprocess like at grinding, the inuencing variables for the specic material removalrate in bevel gear grinding process, such as the feed eand the grinding wheel width , are not constant. More analytically, the differences in feed along the proleheight and the changing contact line along the face width must be accounted for. This results in specic material removal rate which can only be calculated point- by-point and is represented over the whole tooth area. Calculations of this kind forcylindrical gears are performed by [ KLOC0 ]. In simplied approach, for spiral bevel gears, an attempt can be made to approximate conditions to those in standard grinding process (Table 6..6.5 Grinding Spiral Bevel Gears 2 6.5.5.2 Process Parameters Generating Speed, Radial Feed These variables determine the specic material removal rate for the generating and plunge cutting processes. When tooth ank (slot) is being generated, the cradle and the work piece perform combined motion whose result is an octoid tooth ank prole. Therotational speed of the cradle is called the generating speed whose value is deter-mined by the module of the gear and feed per cycle (guide value: 5 /C1per second). The plunge feed denes the speed at which the tool plunges, into the tooth slot, along its axial direction and is determined by the module of the gear and the depthfeed per cycle| Model Type | Bevel-helical gearbox B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 890.000000 |

| Ratio Range | 1 : 80…315 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 35700 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Laos |

| Data Sheet & Drawings | B4-SH-9-D ion LP B V Forced lubrication by motor pum Bevel-helical gearbox B4 |