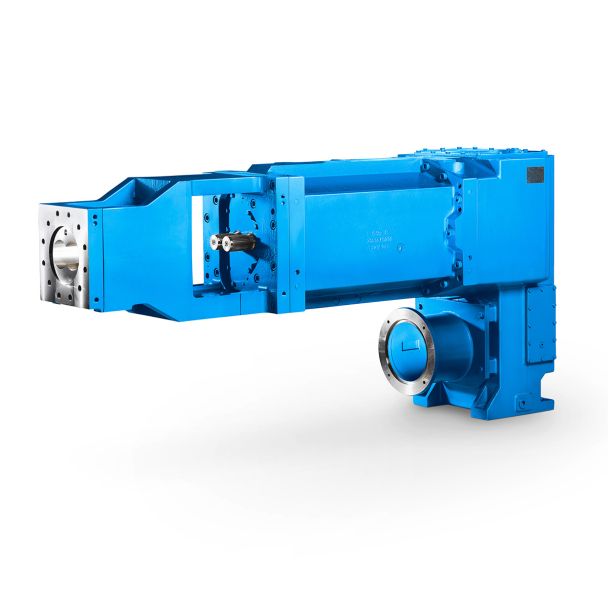

n in every case pure circula tion cooling is also B4-KH-20-A Bevel-helical gearboxes B4

In stock

SKU

B4-KH-20-A

$177,857.14

Flender/Flender Gear Units/Bevel-helical gearboxes B4

ust be cooled after drying and before storage. This is done by using the dryerfan to blow cool air over the bed, or by transferring the grain to an aerated storage bin. Alternate heating and cooling cycles are sometimes invoked

the bed, or by transferring the grain to an aerated storage bin. Alternate heating and cooling cycles are sometimes invoked  to reduce the moisture differential between the drier grain near the perforated oor and the damper grain nearthe top of

to reduce the moisture differential between the drier grain near the perforated oor and the damper grain nearthe top of  the grain column. Some bin dryers have overhead, perforated, cone-shaped drying oors supported about 1 below the roof (Fig. .

the grain column. Some bin dryers have overhead, perforated, cone-shaped drying oors supported about 1 below the roof (Fig. .  heater fan unit is installed below the perforated oor and blows warm air up through the grain. When one batch of dry grain is dropped to perforated oor at the bottom of the bin where it is cooled by an aeration fan, the next batch is loaded and dried on the dryeroor above. Cool, dry grain is transferred to another storage bin by an underoor auger. The advantage of this system is that drying can continue while the grain is being cooled and transferred. Vertical stirring augers may be installed in bin dryers to promote more uniform drying and permit higher airow rate, thus increasing the drying rate for given crop. Although the use of stirring augers may result in slightly lower fuel efciencies, the larger possible batch size, the increased drying rate, and the reduction in quality losses fromoverdrying at the bottom outweigh this disadvantage. 3.1.2 Recirculating Dryers In recirculating dryers, grain is constantly mixed during heating. One example of recircu- lating dryer is shown in Fig. 3. slanted oor causes the grain to move toward verticalauger situated in the center of the dryer. The auger picks up the grain and delivers it tothe top of the grain bin. The result is more uniformly dried crop than that obtained usingnonrecirculating types. Fig. 2 bin dryer with overhead drying oor. 1 Raghavan Fig. 3 Recirculating dryer. The dryer shown in Fig. 4 is used as recirculating batch or continuous-ow dryer. When being used as recirculator, an under grain sweep-auger moves grain to thecenter of

heater fan unit is installed below the perforated oor and blows warm air up through the grain. When one batch of dry grain is dropped to perforated oor at the bottom of the bin where it is cooled by an aeration fan, the next batch is loaded and dried on the dryeroor above. Cool, dry grain is transferred to another storage bin by an underoor auger. The advantage of this system is that drying can continue while the grain is being cooled and transferred. Vertical stirring augers may be installed in bin dryers to promote more uniform drying and permit higher airow rate, thus increasing the drying rate for given crop. Although the use of stirring augers may result in slightly lower fuel efciencies, the larger possible batch size, the increased drying rate, and the reduction in quality losses fromoverdrying at the bottom outweigh this disadvantage. 3.1.2 Recirculating Dryers In recirculating dryers, grain is constantly mixed during heating. One example of recircu- lating dryer is shown in Fig. 3. slanted oor causes the grain to move toward verticalauger situated in the center of the dryer. The auger picks up the grain and delivers it tothe top of the grain bin. The result is more uniformly dried crop than that obtained usingnonrecirculating types. Fig. 2 bin dryer with overhead drying oor. 1 Raghavan Fig. 3 Recirculating dryer. The dryer shown in Fig. 4 is used as recirculating batch or continuous-ow dryer. When being used as recirculator, an under grain sweep-auger moves grain to thecenter of| Model Type | Bevel-helical gearboxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 8300.000000 |

| Ratio Range | 1 : 90…355 |

| Low Speed Output | Hollow shaft with spline acc. to DIN 5480 |

| Nominal Torque | 345000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Macneill Gears Ltd. |

| Country of Manufacture | Mexico |

| Data Sheet & Drawings | n in every case pure circula tion cooling is also B4-KH-20-A Bevel-helical gearboxes B4 |