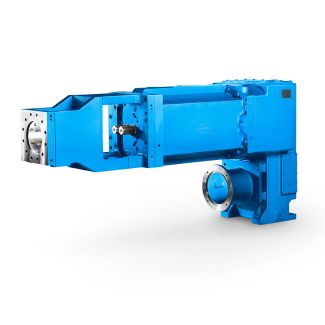

ely if required In case of order shrink disk i B4-CH-28-D Bevel-helical gear Reduction Boxes B4

In stock

SKU

B4-CH-28-D

$561,428.57

Flender/Flender Gear Units/Bevel-helical gear Reduction Boxes B4

the latest pro - duction technology and highly productive manufac- turing plants, Flender meets also in this area he highest standards set by customers from the various industrial sectors. 7Flender supports the pro- duction of copper which is, for example,

standards set by customers from the various industrial sectors. 7Flender supports the pro- duction of copper which is, for example,  used in tele- Flender agent cables. Belt conveyor systems in copper ore mining profit from powerful FLENDER bevel-helical gear units

used in tele- Flender agent cables. Belt conveyor systems in copper ore mining profit from powerful FLENDER bevel-helical gear units  ;FLENDER-PBUC gear units are reliable drives for bucket wheel excavators. 1 0 : 0 8 | diversity of variantsto meet

;FLENDER-PBUC gear units are reliable drives for bucket wheel excavators. 1 0 : 0 8 | diversity of variantsto meet  the requirements - 1 2 : 5 8 | ARPEX couplings and -EUPEX couplings are proving themselves in the chemical industry. Here, drive solutions for delivering and pumping aggressive or hot media or explosion- proof drives are required. Product innovations and improving the development pro- cesses result in changes in technology, costs, and proces- ses. And they result in different behaviour of people. At Flender, innovation processes are not only marked by the willingness of the staff to change and to develop; here the incentive for developing ideas as quickly as possible Bayer AG1 3 : 1 4 | 1 6 : 0 3 | Plastic foils are made in plants equipped with FLENDER single screw extruder gear units. Furthermore, Flender offers standardized double screw extruder gear units for plastics and rubber processing machinery. ( Germany flender HB series gearbox ) makes possible the detailed intro - duction of products and industry-related solutions. With the Net-CAT, the customer can configure complete drive trains, download the CAD drawings, and integrate them into his system. Additionally, in the Flender store he has the opportunity to order products round the clock; even standard product spare parts can be quickly procured. The chemical industry, for example, profits from it, which according to our experience frequently orders from the standard product range. Thus, Flender fulfils customer requirements even f

the requirements - 1 2 : 5 8 | ARPEX couplings and -EUPEX couplings are proving themselves in the chemical industry. Here, drive solutions for delivering and pumping aggressive or hot media or explosion- proof drives are required. Product innovations and improving the development pro- cesses result in changes in technology, costs, and proces- ses. And they result in different behaviour of people. At Flender, innovation processes are not only marked by the willingness of the staff to change and to develop; here the incentive for developing ideas as quickly as possible Bayer AG1 3 : 1 4 | 1 6 : 0 3 | Plastic foils are made in plants equipped with FLENDER single screw extruder gear units. Furthermore, Flender offers standardized double screw extruder gear units for plastics and rubber processing machinery. ( Germany flender HB series gearbox ) makes possible the detailed intro - duction of products and industry-related solutions. With the Net-CAT, the customer can configure complete drive trains, download the CAD drawings, and integrate them into his system. Additionally, in the Flender store he has the opportunity to order products round the clock; even standard product spare parts can be quickly procured. The chemical industry, for example, profits from it, which according to our experience frequently orders from the standard product range. Thus, Flender fulfils customer requirements even f| Model Type | Bevel-helical gear Reduction Boxes B4 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 26200.000000 |

| Ratio Range | 1 : 90…355 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 1400000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | FLENDER ZAHNRADGETRIEBE |

| Country of Manufacture | Estonia |

| Data Sheet & Drawings | ely if required In case of order shrink disk i B4-CH-28-D Bevel-helical gear Reduction Boxes B4 |