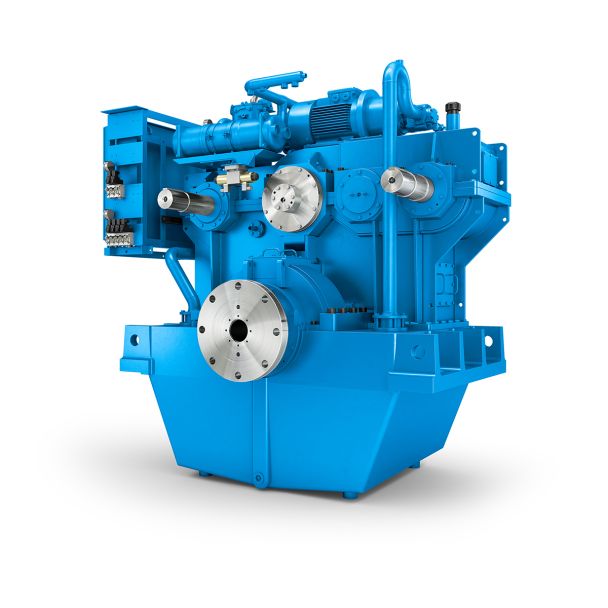

Bevel-helical speed reducers B3 ng position Type H Gear unit dimensions twostage B3-VV15-B

In stock

SKU

B3-VV15-B

$79,928.57

Flender/Flender Gear Units/Bevel-helical speed reducers B3

orces pull on the steering and the more they affect comfort and driving safety. Four-wheel drive vehicles have gained signicant market ground in passenger vehicles providing improved traction power and road safety. Figure 1.3shows transverse engine in four-wheel drive vehicle.

market ground in passenger vehicles providing improved traction power and road safety. Figure 1.3shows transverse engine in four-wheel drive vehicle.  Beside the cylindrical gears for the front axle drive, power take off unit with bevel gears (PTO) is mounted on

Beside the cylindrical gears for the front axle drive, power take off unit with bevel gears (PTO) is mounted on  the output shaft of the gearbox and drives the rear wheels via Cardan shaft and second axle gear with differential.

the output shaft of the gearbox and drives the rear wheels via Cardan shaft and second axle gear with differential.  The two axle drives are linked by means of center differential, compensating differences in the rotation speed of the front and rear axles. common feature in all transverse engine concepts is that they place the power unit ahead of the front axle. This brings advantages in terms of space which is partly outweighed by the greater weight on the front axle. In upmarket cars, longitudinal engine concept with rear-wheel or four-wheel drive prevails. The superior weight distribution has positive effect on driving dynamics and safety. Fig. 1.2 Principle of front-wheel drive with transversely mounted engine Fig. 1.3 Principle of four-wheel drive with transverse engine1.2 Vehicle Transmissions 3 Figure 1.4shows the concept which consists of an engine mounted longitudi- nally to the driving direction, with front- and rear-wheel drive. The engine lies over the front axle and the front axle gear unit is beside or below the engine. This concept has advantages for bodywork design in terms of accident protection for passengers, as the heavy engine is mounted further back in the engine compartment leaving more space for an energy-absorbing design in the front of the vehicle. 1.3 Aircraft Engines Although the volume of bevel gears used worldwide in the automotive sector is the largest, bevel gears also play an essential role in aircraft applications. Bevel gears are used wherever rotary movements have to be transmitted between two non-parallel axes. Typical applications in

The two axle drives are linked by means of center differential, compensating differences in the rotation speed of the front and rear axles. common feature in all transverse engine concepts is that they place the power unit ahead of the front axle. This brings advantages in terms of space which is partly outweighed by the greater weight on the front axle. In upmarket cars, longitudinal engine concept with rear-wheel or four-wheel drive prevails. The superior weight distribution has positive effect on driving dynamics and safety. Fig. 1.2 Principle of front-wheel drive with transversely mounted engine Fig. 1.3 Principle of four-wheel drive with transverse engine1.2 Vehicle Transmissions 3 Figure 1.4shows the concept which consists of an engine mounted longitudi- nally to the driving direction, with front- and rear-wheel drive. The engine lies over the front axle and the front axle gear unit is beside or below the engine. This concept has advantages for bodywork design in terms of accident protection for passengers, as the heavy engine is mounted further back in the engine compartment leaving more space for an energy-absorbing design in the front of the vehicle. 1.3 Aircraft Engines Although the volume of bevel gears used worldwide in the automotive sector is the largest, bevel gears also play an essential role in aircraft applications. Bevel gears are used wherever rotary movements have to be transmitted between two non-parallel axes. Typical applications in| Model Type | Bevel-helical speed reducers B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3730.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 153000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender GmbH |

| Country of Manufacture | China |

| Data Sheet & Drawings | Bevel-helical speed reducers B3 ng position Type H Gear unit dimensions twostage B3-VV15-B |