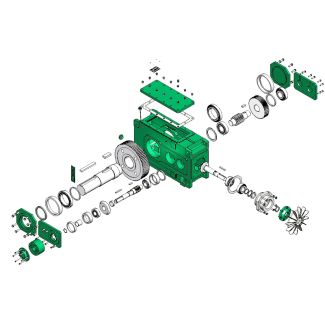

r unit sizes to Threestage gear unit sizes a B3-VH14A Bevel-helical gear unit B3

In stock

SKU

B3-VH14A

$58,928.57

Flender/Flender Gear Units/Bevel-helical gear unit B3

oncentrations in ! waste water was not as successful as ex ected, due to the fact that complexin agents impair the recipitation reactions and the sugstitution of these products proved to % problematic anftedious, the result being that only reduction

the recipitation reactions and the sugstitution of these products proved to % problematic anftedious, the result being that only reduction  of 7% was reached. However, residual heavy metal load of 1.4% can be considered success of this project. The reduction

of 7% was reached. However, residual heavy metal load of 1.4% can be considered success of this project. The reduction  of the quantity of waste water to 4.5% can be achieved even without recycling the rinsing water. However, virtually total

of the quantity of waste water to 4.5% can be achieved even without recycling the rinsing water. However, virtually total  recycling is desirable from the standpoint of material recovery and waste minimisation. In orderto attain thisgoal, individual regeneration processes were tested and, in some cases, applied to the processing solutions on roduction scale. As expected, the organic components proved to be particular problem in tlis context, because many of the substances used change in the course of processing, meanin that reproducible analytical control caused much difficulty. Even the latest analytical metho2 are of no value in this case, because it is frequently not possible to establish clear link between one substance of many and its effect on electrocrystallisation. In addition, the required analytical methods, such as mass, infrared or nuclear resonance spectroscopy, etc., are not generally feasible for electroplating companies, because they are too expensive as regards investments and person- nel. For this reason, the correction of organic processing chemicals will in future conti'nue to be geared to the electrochemical effects (.. Hull cells) and not to the concentration of individual substances. Many organic additives are not directly active in the form in which they are added to the pro- cessing solutions. Clearly, it is the chemical reactions in the solutions and, in part, on the elec- trodes, which yield the actual active substance. Thus,electrocrystallisation remains technique for which analysis alone is not adequateas control instrument. Rather, functional tes

recycling is desirable from the standpoint of material recovery and waste minimisation. In orderto attain thisgoal, individual regeneration processes were tested and, in some cases, applied to the processing solutions on roduction scale. As expected, the organic components proved to be particular problem in tlis context, because many of the substances used change in the course of processing, meanin that reproducible analytical control caused much difficulty. Even the latest analytical metho2 are of no value in this case, because it is frequently not possible to establish clear link between one substance of many and its effect on electrocrystallisation. In addition, the required analytical methods, such as mass, infrared or nuclear resonance spectroscopy, etc., are not generally feasible for electroplating companies, because they are too expensive as regards investments and person- nel. For this reason, the correction of organic processing chemicals will in future conti'nue to be geared to the electrochemical effects (.. Hull cells) and not to the concentration of individual substances. Many organic additives are not directly active in the form in which they are added to the pro- cessing solutions. Clearly, it is the chemical reactions in the solutions and, in part, on the elec- trodes, which yield the actual active substance. Thus,electrocrystallisation remains technique for which analysis alone is not adequateas control instrument. Rather, functional tes| Model Type | Bevel-helical gear unit B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2750.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Flender Svenska AB |

| Country of Manufacture | Belize |

| Data Sheet & Drawings | r unit sizes to Threestage gear unit sizes a B3-VH14A Bevel-helical gear unit B3 |