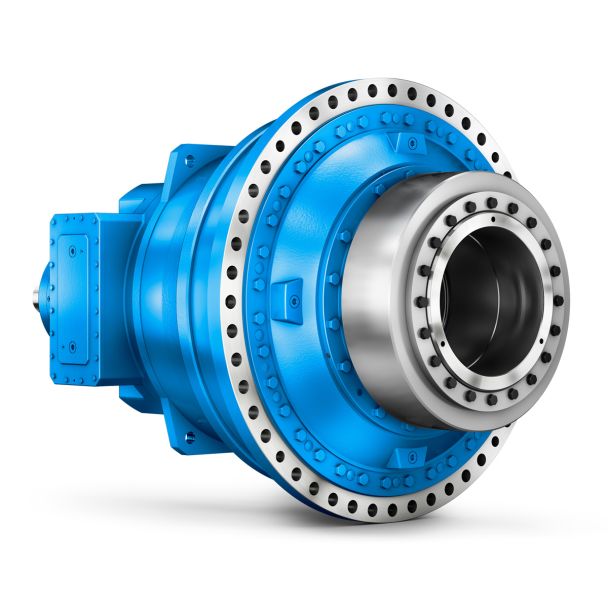

w Selection and ordering data continued Data pos B3-SV-19-D Bevel-helical gear reducer B3

Out of stock

SKU

B3-SV-19-D

$150,000.00

Flender/Flender Gear Units/Bevel-helical gear reducer B3

oise Excitation by Means of Gear Tooth Design . . . ........ 2 0 0 5.2.1 Optimizing the Macro Geometry . . . . . . . . . . . . . . . . . . 2.2.2 Optimizing

. . . . . . . . . . . . . . . . . . 2.2.2 Optimizing  the Micro Geometry . . . . . . . . . . . . . . . . .

the Micro Geometry . . . . . . . . . . . . . . . . .  . . 2.2.3 Inuence of Gear Crowning . . . . . . . . . . . . .

. . 2.2.3 Inuence of Gear Crowning . . . . . . . . . . . . .  . . . . . . . . . 2 5.3 Noise Excitation Governed by Manufacturing .............. 2 1 1 5.3.1 Inuence of Gear Deviations on Transmission Error . . . . 2 5.3.2 Manufacturing Process Inuence on the Transmission Error ....................................... 2 1 7 5.4 Dynamic Noise Excitation . . . . . ....................... 2 2 3 5.4.1 Dynamic of Bevel Gear Running Behavior . . . . . . . . . . . 2.4.2 Calculating Load-Free and Load-Dependent Running Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5.4.3 Test Rig for Rear Axle Gears . . ................... 2 2 6 5.4.4 Test Results ................................. 2 2 7 References ............................................ 2 3 0 6 Manufacturing Process .................................. 2 3 3 6.1 Introduction ....................................... 2 3 3 6.2 Cutting of Spiral Bevel Gears .......................... 2 3 5 6.2.1 Development History . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2.2 Development Trends ........................... 2 3 6 6.2.3 Tools ...................................... 2 3 6Contents xxi 6.2.4 Blade Materials ............................... 2 5 1 6.2.5 Manufacturing Technology ...................... 2 5 1 6.3 Heat Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 6.3.1 Fundamentals of Hardening ...................... 2 5 7 6.3.2 Heat Treatment Processes ....................... 2 5 8 6.3.3 Thermal Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3.4 Thermo-chemical Processes . . .................... 2 5 9 6.3.5 Temperature Proles in Case Hardening ............. 2 6 3 6.3.6 Hardening Distortions . . . . . . . . . . . . . . . . . .

. . . . . . . . . 2 5.3 Noise Excitation Governed by Manufacturing .............. 2 1 1 5.3.1 Inuence of Gear Deviations on Transmission Error . . . . 2 5.3.2 Manufacturing Process Inuence on the Transmission Error ....................................... 2 1 7 5.4 Dynamic Noise Excitation . . . . . ....................... 2 2 3 5.4.1 Dynamic of Bevel Gear Running Behavior . . . . . . . . . . . 2.4.2 Calculating Load-Free and Load-Dependent Running Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 5.4.3 Test Rig for Rear Axle Gears . . ................... 2 2 6 5.4.4 Test Results ................................. 2 2 7 References ............................................ 2 3 0 6 Manufacturing Process .................................. 2 3 3 6.1 Introduction ....................................... 2 3 3 6.2 Cutting of Spiral Bevel Gears .......................... 2 3 5 6.2.1 Development History . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2.2 Development Trends ........................... 2 3 6 6.2.3 Tools ...................................... 2 3 6Contents xxi 6.2.4 Blade Materials ............................... 2 5 1 6.2.5 Manufacturing Technology ...................... 2 5 1 6.3 Heat Treatment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 6.3.1 Fundamentals of Hardening ...................... 2 5 7 6.3.2 Heat Treatment Processes ....................... 2 5 8 6.3.3 Thermal Processes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.3.4 Thermo-chemical Processes . . .................... 2 5 9 6.3.5 Temperature Proles in Case Hardening ............. 2 6 3 6.3.6 Hardening Distortions . . . . . . . . . . . . . . . . . .| Model Type | Bevel-helical gear reducer B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 7000.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 300000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Limited. |

| Country of Manufacture | Netherlands |

| Data Sheet & Drawings | w Selection and ordering data continued Data pos B3-SV-19-D Bevel-helical gear reducer B3 |