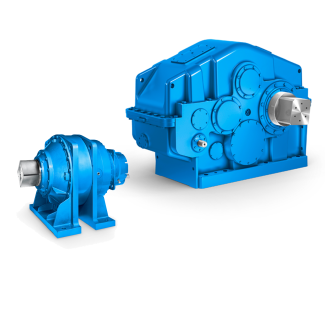

Selection and ordering data continued Article No B3-HV8A Bevel-helical gear Reduction Box B3

In stock

SKU

B3-HV8A

$17,142.86

Flender/Flender Gear Units/Bevel-helical gear Reduction Box B3

r .side or integrated at bevel gear IP 5 enclosure Insulation class ambient temperature of 2C up to +4 quadrilipseal at output shaft solid shaft, hollow shaft or schrink-disc foot-, flange- or torque arm mounting motorintegrated brake, controlled by inverter

at output shaft solid shaft, hollow shaft or schrink-disc foot-, flange- or torque arm mounting motorintegrated brake, controlled by inverter  PTC controlled by inverterBucket Elevator and Conveyor Drives Controlled by Static Inverters The Bucket Elevator and Belt Drives in version

PTC controlled by inverterBucket Elevator and Conveyor Drives Controlled by Static Inverters The Bucket Elevator and Belt Drives in version  Motox-NandMotox-, controlled by Static Frequency Inverters combines full - load mode and maintenance with helical bevel geared motor in one

Motox-NandMotox-, controlled by Static Frequency Inverters combines full - load mode and maintenance with helical bevel geared motor in one  unit. Advantages: -noneed for hydraulic coupling -auxiliary drive not necessary -integrated, adjustable torque limiter for ramps and constant speed -start-up and brake ramp -full-load ratio range up to 2:1 -maintenance mode at reduced output torque up to ratio range of 2:1 -various additional possibilities .. thermistor -up to 7,5 kW motor power inverter is available as motorintegrated version built- in inverter covers all motor capacities MOTOX- Bevel Helical Gear Motors Gear motorK3- M8M4K4- M9S4K6- M1L4K8- M1M4K1- M1M4K1- M1M4K1- G1M4K1- AM2SP4K1- AM2MV4 Rated gear unit torque [Nm] 2 4 8 1 3 4 8 1 2 Output torque 1 3 5 1 2 3 5 9 1 fB 1,5 igear unit 3,7 4,4 3,3 4,8 4,4 4,1 4,9 4,1 4,4 Pmotor at 5 Hz [kW] 0,7 1,1 2,2 4 7,5 1 1,5 3 5 n2load mode [1/min] 2 - 4 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 T2=constant [Nm] 1 3 5 1 2 3 5 9 1 n2min. (maintenance )[1/min] 3 3 3 3 3 3 3 3 3 T2at min.[Nm] 2 5 1 2 3 5 9 1 2 max. attach. brake [Nm] L8 L1 L3 L6 L1 L2 L4 KFB6 KFB6 fmin./fmin.- fmax./ cut-off requency4,5/2- 5/5,8/2- 5/5,5/2- 5/5,3/3- 6/5,6/2- 5/5,9/2- 5/5,9/2- 5/5,6/2- 5/5,3/2- 5/5 Frequency inverter MD4 power rating 0,7 1,5 2,2 4 7,5 1 1,5 3 5 MOTOX-Master IFI...-0,7- 3Ph-AA-1,1-3Ph- -2,2-3Ph- -4- 3Ph-AB-7,5-3Ph- Control panel with cable OMP2 Gear motor p2 k1 kB K3 M8M4 1 6 2 5 5 5 1 1 1 K3-M8M4 1 6 2 5 5 3 7 1 1 K4 M9S4 1 7 2 5 6 6 1 1 1 K4-M9S4 1 7 2 5 6 4 8 1 1 K6 M1L4 1 9 3 6 5 7 5 8 1 1 1 K6-M1L4 1 9 3 6,5

unit. Advantages: -noneed for hydraulic coupling -auxiliary drive not necessary -integrated, adjustable torque limiter for ramps and constant speed -start-up and brake ramp -full-load ratio range up to 2:1 -maintenance mode at reduced output torque up to ratio range of 2:1 -various additional possibilities .. thermistor -up to 7,5 kW motor power inverter is available as motorintegrated version built- in inverter covers all motor capacities MOTOX- Bevel Helical Gear Motors Gear motorK3- M8M4K4- M9S4K6- M1L4K8- M1M4K1- M1M4K1- M1M4K1- G1M4K1- AM2SP4K1- AM2MV4 Rated gear unit torque [Nm] 2 4 8 1 3 4 8 1 2 Output torque 1 3 5 1 2 3 5 9 1 fB 1,5 igear unit 3,7 4,4 3,3 4,8 4,4 4,1 4,9 4,1 4,4 Pmotor at 5 Hz [kW] 0,7 1,1 2,2 4 7,5 1 1,5 3 5 n2load mode [1/min] 2 - 4 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 1 - 3 T2=constant [Nm] 1 3 5 1 2 3 5 9 1 n2min. (maintenance )[1/min] 3 3 3 3 3 3 3 3 3 T2at min.[Nm] 2 5 1 2 3 5 9 1 2 max. attach. brake [Nm] L8 L1 L3 L6 L1 L2 L4 KFB6 KFB6 fmin./fmin.- fmax./ cut-off requency4,5/2- 5/5,8/2- 5/5,5/2- 5/5,3/3- 6/5,6/2- 5/5,9/2- 5/5,9/2- 5/5,6/2- 5/5,3/2- 5/5 Frequency inverter MD4 power rating 0,7 1,5 2,2 4 7,5 1 1,5 3 5 MOTOX-Master IFI...-0,7- 3Ph-AA-1,1-3Ph- -2,2-3Ph- -4- 3Ph-AB-7,5-3Ph- Control panel with cable OMP2 Gear motor p2 k1 kB K3 M8M4 1 6 2 5 5 5 1 1 1 K3-M8M4 1 6 2 5 5 3 7 1 1 K4 M9S4 1 7 2 5 6 6 1 1 1 K4-M9S4 1 7 2 5 6 4 8 1 1 K6 M1L4 1 9 3 6 5 7 5 8 1 1 1 K6-M1L4 1 9 3 6,5| Model Type | Bevel-helical gear Reduction Box B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 800.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 27200 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | FLENDER TÜBINGEN GMBH |

| Country of Manufacture | China |

| Data Sheet & Drawings | Selection and ordering data continued Article No B3-HV8A Bevel-helical gear Reduction Box B3 |