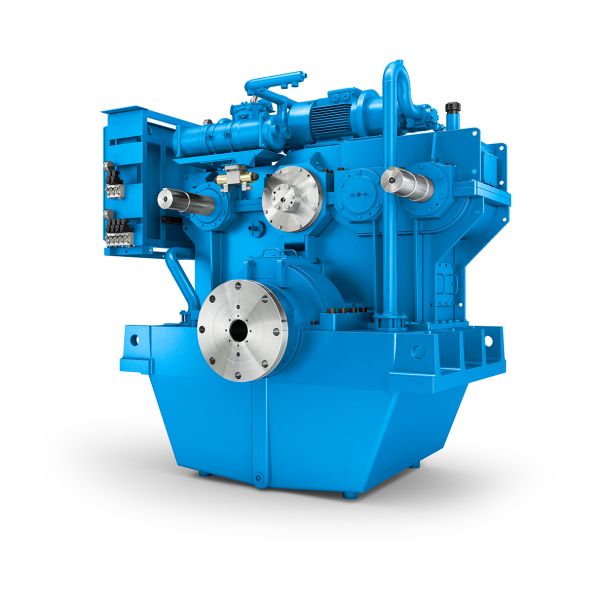

Flender GmbH Flender MD Helical gear units v B3-HV17-B Bevel-helical gearbox B3

In stock

SKU

B3-HV17-B

$106,928.57

Flender/Flender Gear Units/Bevel-helical gearbox B3

r of oranges in the world, followed by the United States and Mexico. Citrus processing is one of the most important food industries of the world. The main processed products of the industry are juice and juice concentrate. During the

important food industries of the world. The main processed products of the industry are juice and juice concentrate. During the  production ofcitrus juice, large amount of processing residue, consisting of peel and rag, pulp wash,and seed, which amounts to about

production ofcitrus juice, large amount of processing residue, consisting of peel and rag, pulp wash,and seed, which amounts to about  5%6%, is generated (. Citrus waste is rich source of essential oils, pectin, and variety of by-products, including cattle feed.

5%6%, is generated (. Citrus waste is rich source of essential oils, pectin, and variety of by-products, including cattle feed.  Kester- son and Braddock ( have reviewed the processing details of by-products and specialty products of Florida citrus. 2.3.1 Dried Citrus Pulp and MolassesThe majority of citrus processing waste is converted into dried citrus pulp and used as cattle feed. It is low in crude proteins, ber, and fat but rich in carbohydrates. The low bulk density of dried citrus pulp results in high storage and handling costs, which have led to the development of the palletizing industry. Citrus molasses is made from pressed liquor obtained during the manufacture of dried citrus pulp. The liquor contains 9%1% soluble solids, of which 6%7% are sugars. Citrus molasses is similar to cane molasses and is widely used as an animal feedand can be converted into alcohol by fermentation and for production of yeast, vinegar,2,3-butyl glycol, riboavin, and citric acid (. Table 3 Major Countries Producing Oranges Production ( Country (1 MT) Brazil 2,9United States 1,5 Mexico 4,0 India 2,0Italy 2,0China 2,3 Iran 1,6 Pakistan 1,4 World 6,8 Source : From Ref. 1. 8 Eipeson and Ramteke 2.3.2 Citrus Peel Oil The avedo portion of the peel contains numerous oil cells, which on crushing or punctur- ing eject oil. Fresh orange peel yields about 0.5% oil by the cold press method (. Thecitrus peel oil has attained great commercial importance in the avoring of several kinds of beverages, confectionery, and bakery products. It is also used in cosmetics and perfum- ery. The purity of citrus oils is determined

Kester- son and Braddock ( have reviewed the processing details of by-products and specialty products of Florida citrus. 2.3.1 Dried Citrus Pulp and MolassesThe majority of citrus processing waste is converted into dried citrus pulp and used as cattle feed. It is low in crude proteins, ber, and fat but rich in carbohydrates. The low bulk density of dried citrus pulp results in high storage and handling costs, which have led to the development of the palletizing industry. Citrus molasses is made from pressed liquor obtained during the manufacture of dried citrus pulp. The liquor contains 9%1% soluble solids, of which 6%7% are sugars. Citrus molasses is similar to cane molasses and is widely used as an animal feedand can be converted into alcohol by fermentation and for production of yeast, vinegar,2,3-butyl glycol, riboavin, and citric acid (. Table 3 Major Countries Producing Oranges Production ( Country (1 MT) Brazil 2,9United States 1,5 Mexico 4,0 India 2,0Italy 2,0China 2,3 Iran 1,6 Pakistan 1,4 World 6,8 Source : From Ref. 1. 8 Eipeson and Ramteke 2.3.2 Citrus Peel Oil The avedo portion of the peel contains numerous oil cells, which on crushing or punctur- ing eject oil. Fresh orange peel yields about 0.5% oil by the cold press method (. Thecitrus peel oil has attained great commercial importance in the avoring of several kinds of beverages, confectionery, and bakery products. It is also used in cosmetics and perfum- ery. The purity of citrus oils is determined| Model Type | Bevel-helical gearbox B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 4990.000000 |

| Ratio Range | 1 : 12.5…71 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 200000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | flanders electric peru s a c |

| Country of Manufacture | Greece |

| Data Sheet & Drawings | Flender GmbH Flender MD Helical gear units v B3-HV17-B Bevel-helical gearbox B3 |