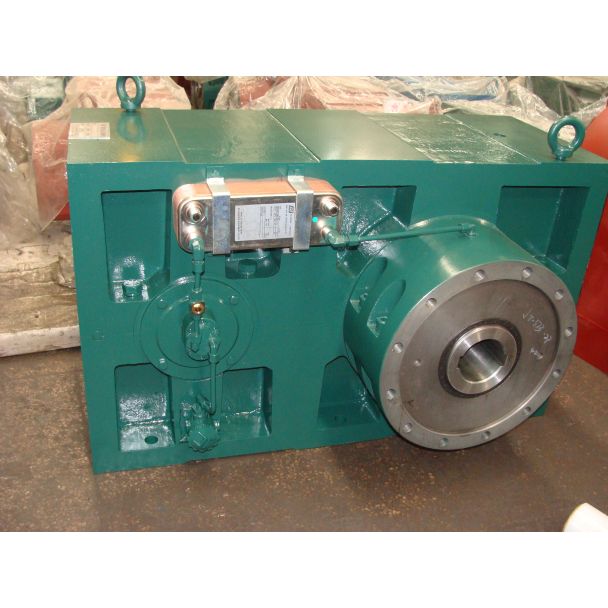

Article No and Article No supplement for th B3-HH-23-D Bevel-helical gear units B3

In stock

SKU

B3-HH-23-D

$257,142.86

Flender/Flender Gear Units/Bevel-helical gear units B3

pulse-processing machinery are given in Appen-dix II. 3.1 Cleaning and Grading Pulses must be cleaned during the process, because they may be delivered containing up to 2% impurities. Foreign materials include pod walls, broken branches, soil, cereals,oilseeds, weed seeds, diseased

may be delivered containing up to 2% impurities. Foreign materials include pod walls, broken branches, soil, cereals,oilseeds, weed seeds, diseased  and deformed seeds, and stones. Initial cleaning of lentilstakes place on scalpers and airscreens. Raw material is cleaned by removing

and deformed seeds, and stones. Initial cleaning of lentilstakes place on scalpers and airscreens. Raw material is cleaned by removing  dust, dirt, foreign material, off-sized, imma- ture, and infested grains. The cleaned grain is graded into uniform sizes. Air and

dust, dirt, foreign material, off-sized, imma- ture, and infested grains. The cleaned grain is graded into uniform sizes. Air and  rotaryscreens with round holes are used for cleaning. In rotary screens, however, the grain doesnot have equal opportunity to come in contact with the sieve before reaching the end ofthe separation zone, which leads to improper grading. After the lentils are conditioned with water and tempered, the seeds are graded on round-hole rotary screens. The graded seeds are then dehulled, and the mixture of whole and split lentils, hulls, broken seed, and nes are passed through an inclined gravity separa-tor to remove broken seed and ne particles. Whole seeds are screened from splits andare returned to the dehuller. The splits are fed into horizontal gravity separator to separatedehulled from hulled splits. Normally, two types of cleaners are available: rotary screen cleaners and reciprocat- ing screen cleaners. The screens are used to remove the foreign materials on the basis of size difference. The suction fan removes lighter material such as dust particles. The separa- tion of splits from whole grain is done by the screens (. The rotary screen consists of four compartments of different-sized screens tted on 5-mmdiameter shaft. The screens clean different pulse crops. The machine is tted ona sloped foundation (slope 5 mm for 1 length) and is operated at low speed (1 Dehulling and Splitting Pulses 4 3 rpm) for better performance. The body of machine can be made of wood or iron (mild steel), depending on the manufacturer or custome

rotaryscreens with round holes are used for cleaning. In rotary screens, however, the grain doesnot have equal opportunity to come in contact with the sieve before reaching the end ofthe separation zone, which leads to improper grading. After the lentils are conditioned with water and tempered, the seeds are graded on round-hole rotary screens. The graded seeds are then dehulled, and the mixture of whole and split lentils, hulls, broken seed, and nes are passed through an inclined gravity separa-tor to remove broken seed and ne particles. Whole seeds are screened from splits andare returned to the dehuller. The splits are fed into horizontal gravity separator to separatedehulled from hulled splits. Normally, two types of cleaners are available: rotary screen cleaners and reciprocat- ing screen cleaners. The screens are used to remove the foreign materials on the basis of size difference. The suction fan removes lighter material such as dust particles. The separa- tion of splits from whole grain is done by the screens (. The rotary screen consists of four compartments of different-sized screens tted on 5-mmdiameter shaft. The screens clean different pulse crops. The machine is tted ona sloped foundation (slope 5 mm for 1 length) and is operated at low speed (1 Dehulling and Splitting Pulses 4 3 rpm) for better performance. The body of machine can be made of wood or iron (mild steel), depending on the manufacturer or custome| Model Type | Bevel-helical gear units B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 12000.000000 |

| Ratio Range | 1 : 20…71 |

| Low Speed Output | Hollow shaft with keyway acc. to DIN 6885/1 |

| Nominal Torque | 640000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | N.V. Flender Belge S.A. |

| Country of Manufacture | Tajikistan |

| Data Sheet & Drawings | Article No and Article No supplement for th B3-HH-23-D Bevel-helical gear units B3 |