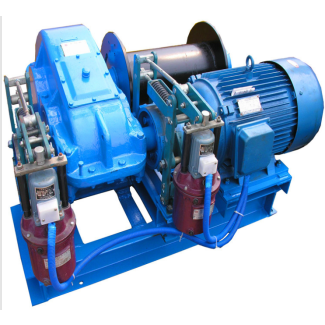

A A E l ee G G a Shaft seals see page onwards B3-DH-14B Bevel-helical gear boxes B3

In stock

SKU

B3-DH-14B

$58,928.57

Flender/Flender Gear Units/Bevel-helical gear boxes B3

ray dryers. In addition, they have semicontinuous operation. This type of dryer is very popular for drying fruits and vegetables. As comparedto that of tray dryer, the investment cost is higher. typical dryer may be more than 2 long with

As comparedto that of tray dryer, the investment cost is higher. typical dryer may be more than 2 long with  square or rectangular cross section of 2 /H1 . The wet material is loaded into trays that are stacked on

square or rectangular cross section of 2 /H1 . The wet material is loaded into trays that are stacked on  trolleys (Fig. . The trolleys are introduced periodi-cally into one end of the tunnel (the wet end), advance through the

trolleys (Fig. . The trolleys are introduced periodi-cally into one end of the tunnel (the wet end), advance through the  tunnel, and areremoved at the other end (the dry end). typical tunnel dryer can be operated in acocurrent or countercurrent ow of air and trolleys. Two-stage dryers that feature shortcocurrent stage followed by longer countercurrent stage are also used. In cross-ow designs the drying air moves at right angles to the path of the trays of food. Basic modeling principles for this type of drying are similar to that of cabinet dryer. The drying timesare similar to those in cabinet tray drying, and the airow rate is linked to the total numberof trays. The dimensions of the tunnel are calculated on the basis of the necessary dryingthroughput, necessary drying time, and dimensions and capacity of single trolley. Infor-mation on the design, constructional details, and operation of these dryers has been pub- lished (1,2,. 3.2.3 Conveyor-Type Dryers Fully continuous drying operation is achieved in conveyor, belt, or band dryers. This type of dryer is very popular in the fruit and vegetable processing industry. The wet productformed or placed in bed of different thicknesses is carried through tunnel on perforated(mesh, slotted, or louvered) conveyors. Heated air is directed up or down through the conveyor and the layer of the product, usually up in the early drying stages and down toward the dry product exit, or directed across the material surface for products in thinlayers on nonperforated band. Some models consist of two or more conveyors in series. Also, either cocurrent or countercurrent congurations

tunnel, and areremoved at the other end (the dry end). typical tunnel dryer can be operated in acocurrent or countercurrent ow of air and trolleys. Two-stage dryers that feature shortcocurrent stage followed by longer countercurrent stage are also used. In cross-ow designs the drying air moves at right angles to the path of the trays of food. Basic modeling principles for this type of drying are similar to that of cabinet dryer. The drying timesare similar to those in cabinet tray drying, and the airow rate is linked to the total numberof trays. The dimensions of the tunnel are calculated on the basis of the necessary dryingthroughput, necessary drying time, and dimensions and capacity of single trolley. Infor-mation on the design, constructional details, and operation of these dryers has been pub- lished (1,2,. 3.2.3 Conveyor-Type Dryers Fully continuous drying operation is achieved in conveyor, belt, or band dryers. This type of dryer is very popular in the fruit and vegetable processing industry. The wet productformed or placed in bed of different thicknesses is carried through tunnel on perforated(mesh, slotted, or louvered) conveyors. Heated air is directed up or down through the conveyor and the layer of the product, usually up in the early drying stages and down toward the dry product exit, or directed across the material surface for products in thinlayers on nonperforated band. Some models consist of two or more conveyors in series. Also, either cocurrent or countercurrent congurations| Model Type | Bevel-helical gear boxes B3 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 2750.000000 |

| Ratio Range | 1 : 16…90 |

| Low Speed Output | Hollow shaft with shrink disk |

| Nominal Torque | 113000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | flanders electric peru s a c |

| Country of Manufacture | Turkey |

| Data Sheet & Drawings | A A E l ee G G a Shaft seals see page onwards B3-DH-14B Bevel-helical gear boxes B3 |