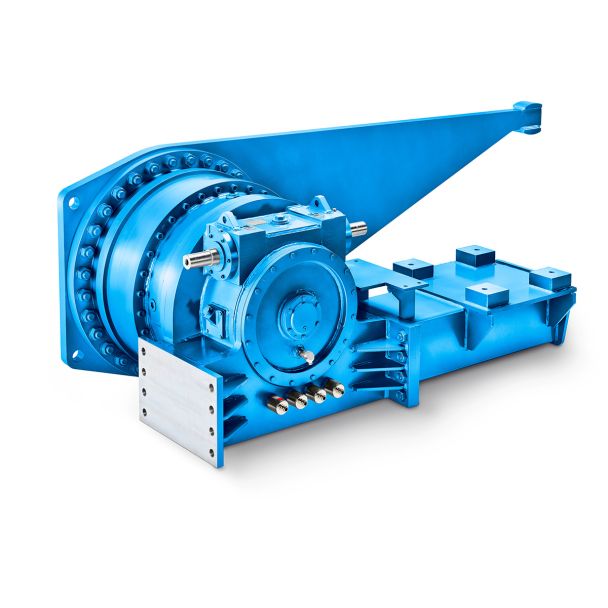

Bevel-helical gear box B2 H M LP For combinations of type H gea B2FV-5-C

In stock

SKU

B2FV-5-C

$345,000.00

Flender/Flender Gear Units/Bevel-helical gear box B2

nsport, are included in ASHRAE (. In the design of mechanical refrigeration systems for trucks and trailers, manufacturers normally use computer pro-grams or charts to match the refrigeration unit to the vehicle used for specic operations. 3.2 Temperature Control Systems

computer pro-grams or charts to match the refrigeration unit to the vehicle used for specic operations. 3.2 Temperature Control Systems  Different systems are available to maintain optimal temperatures in transport vehicles. Mechanical refrigeration, ice cooling, and cryogenic cooling are the

Different systems are available to maintain optimal temperatures in transport vehicles. Mechanical refrigeration, ice cooling, and cryogenic cooling are the  three most commonly used methods. Other methods are also available, depending on the mode of transport.Basic concepts of the cooling

three most commonly used methods. Other methods are also available, depending on the mode of transport.Basic concepts of the cooling  methods are presented here, other cooling methods arepresented in Sec. 5. 5 Hui et al. 3.2.1 Mechanical Refrigeration Mechanical refrigeration is the most widely used cooling method in road and rail transport. It has also gained popularity in marine and intermodal transport. Similar to householdrefrigerators, mechanical refrigeration systems used in transport vehicles operate on the vapor-compression-refrigeration cycle (Wark, . In such systems, refrigerant changes phase from liquid to vapor and back to liquid in closed cycle. As result ofthese phase changes, the refrigerant is able to absorb heat in the evaporator located withinthe vehicle and release it through the condenser into the air outside the vehicle. The main components of mechanical refrigeration system are the evaporator, com- pressor, condenser, and expansion valve. In the evaporator, the liquid refrigerant absorbs heat from the warm air surrounding the produce and changes into vapor. The vaporized refrigerant is then compressed by the compressor to pressure high enough to allowthe refrigerant to release heat and condense at ambient temperature inside the condenser. Depending on the cargo temperature, variable amount of liqueed refrigerant is released through the expansion valve into the evaporator, where it continues the cycle and maintainsthe desired temperature inside the vehicle. The refrigeration unit may be driven by diesel engine, an

methods are presented here, other cooling methods arepresented in Sec. 5. 5 Hui et al. 3.2.1 Mechanical Refrigeration Mechanical refrigeration is the most widely used cooling method in road and rail transport. It has also gained popularity in marine and intermodal transport. Similar to householdrefrigerators, mechanical refrigeration systems used in transport vehicles operate on the vapor-compression-refrigeration cycle (Wark, . In such systems, refrigerant changes phase from liquid to vapor and back to liquid in closed cycle. As result ofthese phase changes, the refrigerant is able to absorb heat in the evaporator located withinthe vehicle and release it through the condenser into the air outside the vehicle. The main components of mechanical refrigeration system are the evaporator, com- pressor, condenser, and expansion valve. In the evaporator, the liquid refrigerant absorbs heat from the warm air surrounding the produce and changes into vapor. The vaporized refrigerant is then compressed by the compressor to pressure high enough to allowthe refrigerant to release heat and condense at ambient temperature inside the condenser. Depending on the cargo temperature, variable amount of liqueed refrigerant is released through the expansion valve into the evaporator, where it continues the cycle and maintainsthe desired temperature inside the vehicle. The refrigeration unit may be driven by diesel engine, an| Model Type | Bevel-helical gear box B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 16100.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Flanged shaft |

| Nominal Torque | 9400 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender Ltd., China |

| Country of Manufacture | Germany |

| Data Sheet & Drawings | Bevel-helical gear box B2 H M LP For combinations of type H gea B2FV-5-C |