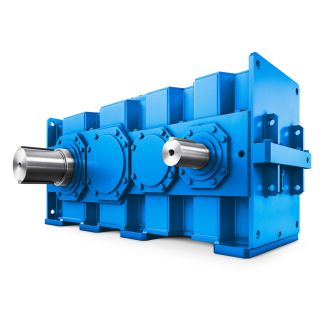

specifications continued Nominal output torque B2-VV-7-A Bevel-helical gear reducers B2

In stock

SKU

B2-VV-7-A

$18,750.00

Flender/Flender Gear Units/Bevel-helical gear reducers B2

m 1/1 Flender MD 2.1 2Options for operation Cooling Additional cooling options Overview Further cooling options can be implemented the selection is made via the configurator using the "Other cooling" option, order code Y3 the desired cooling option can then

selection is made via the configurator using the "Other cooling" option, order code Y3 the desired cooling option can then  be defined in plain text. Oil-to-water cooler This option allows the precise dimensioning of the cooling, even for dissipating heat

be defined in plain text. Oil-to-water cooler This option allows the precise dimensioning of the cooling, even for dissipating heat  quantities that are bigger than can be accomplished using the cooling coil. To this end, the gear unit is equipped

quantities that are bigger than can be accomplished using the cooling coil. To this end, the gear unit is equipped  with motor-driven or flange-mounted pump and the oil is directed through the cooler during operation. This option does not require forced lubrication in every case, pure circula- tion cooling is also possible. To ensure the functionality, pres- sure sensor can be installed in the oil line and/or temperature sensor can be installed in the oil sump. filter can be installed to improve the oil quality and thus to improve the service life. Refer to the Filter chapter ( from page 1/4 ). The cooling coil can be designed in the bidding phase by specifying the technical requirements and boundary conditions. The pump assignment and the attaching of the oil-water heat exchanger is standardized. ) Bundled tube heat exchanger bundled tube heat exchanger can be used for cooling (suitable for fresh water and sea water). Example: H1SH0 with flange-mounted pump and oil-water cooler ) Plate heat exchanger plate heat exchanger can be used for cooling (not suitable for sea water).Example: B2SV0 with forced lubrication, motor pump and plate cooler (solution for variable speeds) Electrically driven fan An electrically driven fan can be installed. Cooling can take place with this, regardless of the operating state of the gear unit (.. not at low ambient temperatures, when an oil temperature limit is exceeded or in the event of variable speeds). To optimally utilize the advantages of this cooling option, control via tempera- ture monitoring is required. The heat d

with motor-driven or flange-mounted pump and the oil is directed through the cooler during operation. This option does not require forced lubrication in every case, pure circula- tion cooling is also possible. To ensure the functionality, pres- sure sensor can be installed in the oil line and/or temperature sensor can be installed in the oil sump. filter can be installed to improve the oil quality and thus to improve the service life. Refer to the Filter chapter ( from page 1/4 ). The cooling coil can be designed in the bidding phase by specifying the technical requirements and boundary conditions. The pump assignment and the attaching of the oil-water heat exchanger is standardized. ) Bundled tube heat exchanger bundled tube heat exchanger can be used for cooling (suitable for fresh water and sea water). Example: H1SH0 with flange-mounted pump and oil-water cooler ) Plate heat exchanger plate heat exchanger can be used for cooling (not suitable for sea water).Example: B2SV0 with forced lubrication, motor pump and plate cooler (solution for variable speeds) Electrically driven fan An electrically driven fan can be installed. Cooling can take place with this, regardless of the operating state of the gear unit (.. not at low ambient temperatures, when an oil temperature limit is exceeded or in the event of variable speeds). To optimally utilize the advantages of this cooling option, control via tempera- ture monitoring is required. The heat d| Model Type | Bevel-helical gear reducers B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 875.000000 |

| Ratio Range | 1 : 5…18 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 with reinforced spigot |

| Nominal Torque | 19000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | WALTHER FLENDER GMBH |

| Country of Manufacture | China |

| Data Sheet & Drawings | specifications continued Nominal output torque B2-VV-7-A Bevel-helical gear reducers B2 |