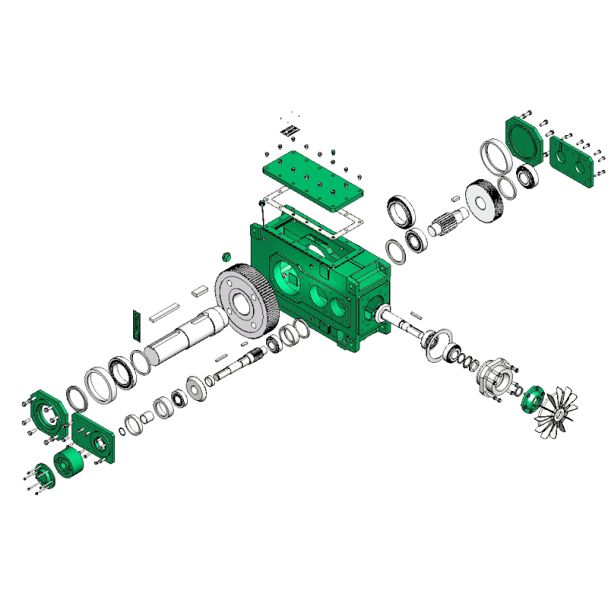

speed shaft LSS gear unit sizes to Technical sp B2-SV-17-D Bevel-helical gear reducer B2

In stock

SKU

B2-SV-17-D

$18,750.00

Flender/Flender Gear Units/Bevel-helical gear reducer B2

lled barley 4Pearled and half-split barley 3Pearled, half-split, and rolled barley 2 3 Sarkar Table 3 Pearled Barley Yield Percentage by Application Application Pearled barley yield (%) Rice extender 5 Miso 7 Shochu alcohol 6 1.2.5.3 North Africa In some

by Application Application Pearled barley yield (%) Rice extender 5 Miso 7 Shochu alcohol 6 1.2.5.3 North Africa In some  parts of the world, such as Morocco and Tunisia, the hulled barley would serve as raw material to the milling

parts of the world, such as Morocco and Tunisia, the hulled barley would serve as raw material to the milling  section where rollermills, sifters, and puriers may be used for further processing. The processing objectives would involve the following: 1.

section where rollermills, sifters, and puriers may be used for further processing. The processing objectives would involve the following: 1.  Size reduction to suit various product application requirements 2. Further purication of the product Light pearling coupled with this additional processing helps boost the extraction rate while offering different granulation and renement for creative product mix (Fig. . Table 4 is an example of the nished products, extraction rates, and application of the milled barley in that region. barley mill would also normally produce some pearledbarley in addition to the other granular nished products as given in Table 5. The milling process involves cleaning the barley as it passes through intermediate storage bins to the barley pearlers placed in series of rst-, second- and third-pearling operations. In each stage of the pearling operation there may be one or more pearlers, as necessary, to split the load. The barley-milling capacity, for example, may be 1.0 /. Ifeach pearler handled 5 kg/, there would then be requirement for two separate pearl-ing lines. Each pearler may use 2-hp motor. Therefore, it is too expensive to pearl Fig. 7 Milled barley products in North Africa. Specialty Milling 3 Table 4 Milled Barley Products, Extraction Rates, and Their Application Products Extraction rate (%) End use application Coarse semolina 4 Couscous Medium semolina 4 Couscous Fine semolina 4 SoupFlour 2 BreadBran 2 Feed from power-consumption standpoint. In each stage of pearling approximately 8% of the hulled material is removed. Depending on the type of barley being processed,2%

Size reduction to suit various product application requirements 2. Further purication of the product Light pearling coupled with this additional processing helps boost the extraction rate while offering different granulation and renement for creative product mix (Fig. . Table 4 is an example of the nished products, extraction rates, and application of the milled barley in that region. barley mill would also normally produce some pearledbarley in addition to the other granular nished products as given in Table 5. The milling process involves cleaning the barley as it passes through intermediate storage bins to the barley pearlers placed in series of rst-, second- and third-pearling operations. In each stage of the pearling operation there may be one or more pearlers, as necessary, to split the load. The barley-milling capacity, for example, may be 1.0 /. Ifeach pearler handled 5 kg/, there would then be requirement for two separate pearl-ing lines. Each pearler may use 2-hp motor. Therefore, it is too expensive to pearl Fig. 7 Milled barley products in North Africa. Specialty Milling 3 Table 4 Milled Barley Products, Extraction Rates, and Their Application Products Extraction rate (%) End use application Coarse semolina 4 Couscous Medium semolina 4 Couscous Fine semolina 4 SoupFlour 2 BreadBran 2 Feed from power-consumption standpoint. In each stage of pearling approximately 8% of the hulled material is removed. Depending on the type of barley being processed,2%| Model Type | Bevel-helical gear reducer B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 875.000000 |

| Ratio Range | 1 : 5.6…18 |

| Low Speed Output | Solid shaft with parallel key acc. to DIN 6885/1 |

| Nominal Torque | 195000 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Siemens AG |

| Country of Manufacture | China |

| Data Sheet & Drawings | speed shaft LSS gear unit sizes to Technical sp B2-SV-17-D Bevel-helical gear reducer B2 |