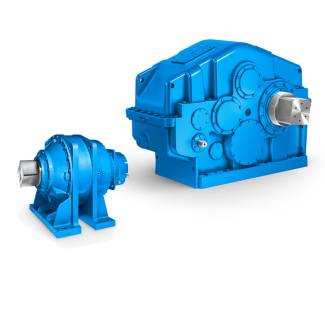

Bevel-helical gearboxes B2 ies PG kW type B n rpm continued o n r e q u B2-CV8A

In stock

SKU

B2-CV8A

$83,035.71

Flender/Flender Gear Units/Bevel-helical gearboxes B2

meshing or in bearings, as well asto measure their growth over time. Due to the high speed and therelatively short growth time of the damage, it is operationally saferto apply an autonomous diagnostic system for the turbodrives thatautomatically monitors the

growth time of the damage, it is operationally saferto apply an autonomous diagnostic system for the turbodrives thatautomatically monitors the  state of vibrations, detects and analyzesdeviations in the frequency spectra, and transmits -mails via theInternet. The gear controller device in

state of vibrations, detects and analyzesdeviations in the frequency spectra, and transmits -mails via theInternet. The gear controller device in  Figure 1 enables frequencyanalyses with 8 lines and resolution rate of 1 dB, combinedwith measuring times of up to 1

Figure 1 enables frequencyanalyses with 8 lines and resolution rate of 1 dB, combinedwith measuring times of up to 1  minutes.Figure 1. Moto-Compressor Unit with Attached Gear Controller Device. Figure 1. Local Damage on Gearbox Teeth. Some machine operators want to know the time that the machine can still be operated safely, .., to planned yearly shutdown afterthe gear controller has signaled the first signs of damage. Toanalyze the degree of the damage to the drive, the diagnosticspecialists should always have access to the diagnostic system. Inthe case of pending damages, the specialist can remotely startadditional measurements that provide additional data for preciseevaluation of the problem. Analysis can become more difficult if startup or torque- oscillating modes are also included in the evaluation. Torquemeasurements with strain gauges may be required. The monitoringsystem then load-dependently triggers these nonstationaryoperations, .., torque measurement during startup. Measuringresults are then automatically transmitted to the gear unit specialistvia the Internet. Gear controller devices in Internet-technology are autonomous and contain robust embedded measuring, analysis, and control systems in modular design. They implement the functions of an intelligent data logger, an event-recorder, classifier, as well as ananalysis and diagnostic computer. All commercially availablevibration sensors and even strain gauges can be directly connectedto the device without the addition of special interfaces for datapreparation or sensor supply. Hardware components have

minutes.Figure 1. Moto-Compressor Unit with Attached Gear Controller Device. Figure 1. Local Damage on Gearbox Teeth. Some machine operators want to know the time that the machine can still be operated safely, .., to planned yearly shutdown afterthe gear controller has signaled the first signs of damage. Toanalyze the degree of the damage to the drive, the diagnosticspecialists should always have access to the diagnostic system. Inthe case of pending damages, the specialist can remotely startadditional measurements that provide additional data for preciseevaluation of the problem. Analysis can become more difficult if startup or torque- oscillating modes are also included in the evaluation. Torquemeasurements with strain gauges may be required. The monitoringsystem then load-dependently triggers these nonstationaryoperations, .., torque measurement during startup. Measuringresults are then automatically transmitted to the gear unit specialistvia the Internet. Gear controller devices in Internet-technology are autonomous and contain robust embedded measuring, analysis, and control systems in modular design. They implement the functions of an intelligent data logger, an event-recorder, classifier, as well as ananalysis and diagnostic computer. All commercially availablevibration sensors and even strain gauges can be directly connectedto the device without the addition of special interfaces for datapreparation or sensor supply. Hardware components have| Model Type | Bevel-helical gearboxes B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 3875.000000 |

| Ratio Range | 1 : 6.3…22.4 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 23800 Nm |

| Mounting Arrangements | Vertical mounting position |

| Manufacturer | Flender de Colombia |

| Country of Manufacture | Indonesia |

| Data Sheet & Drawings | Bevel-helical gearboxes B2 ies PG kW type B n rpm continued o n r e q u B2-CV8A |