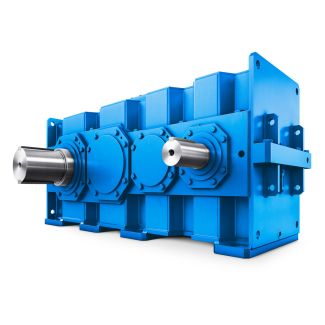

B2-CH18-B peed shaft LSS gear unit sizes to Technical spec Bevel-helical gear reducer B2

In stock

SKU

B2-CH18-B

$30,000.00

Flender/Flender Gear Units/Bevel-helical gear reducer B2

ment capacity of 1.6Mta and each would be supplied with Loesche VRM with 2tph of grinding capacity. The Dadri project is situated near New Delhi and the Nalagarh mill is located further to the north, close to the Himalayas. It

is situated near New Delhi and the Nalagarh mill is located further to the north, close to the Himalayas. It  became apparent that the grinding stations would need to be operated without hot gas generator and consequently water injection for

became apparent that the grinding stations would need to be operated without hot gas generator and consequently water injection for  the purpose of grinding bed stabilisation was not permitted. Loesche looked at the customers requirements before deciding on the best

the purpose of grinding bed stabilisation was not permitted. Loesche looked at the customers requirements before deciding on the best  solution. The main constituents to be ground were clinker, fly OPTIMISED GRINDING Figure 3: assumed grindability for Ambuja Cements Dadri and Nalagarh projects JUNE 2 INTERNATIONAL CEMENT REVIEWmills, Loesche has support roller and master roller. The roller is solely to prepare and stabilise the grinding bed. The most difficult thing to achieve when producing cement is to keep the grinding bed stable. In comparison to raw material grinding, with cement milling there are more fines and some parts of the grinding bed tend to become partly fluidised, caused by entrapped air. This reduces the internal friction within the material layer making it difficult to efficiently apply the grinding forces. So the roller removes the air from the grinding bed and prepares the material for the master roller to carry out the grinding. The flowsheet for grinding system with VRM (see Figure shows that, after the classifier, product is precipitated and then recovered from the bag filter. system fan provides the draft through the machine and different sources of hot gases can be utilized if required. Furthermore wide range of feed materials are tolerated and conveyed to the mill via the feeding system. Ambuja Cements Dadri and Nalagarh grinding stations In 2, Loesche received an enquiry for two grinding stations in India. Both would have cement capacity of 1.6Mta and each would be supplied with Loesche VRM with 2tph of grinding capacity. The Dadri project is situated near New Del

solution. The main constituents to be ground were clinker, fly OPTIMISED GRINDING Figure 3: assumed grindability for Ambuja Cements Dadri and Nalagarh projects JUNE 2 INTERNATIONAL CEMENT REVIEWmills, Loesche has support roller and master roller. The roller is solely to prepare and stabilise the grinding bed. The most difficult thing to achieve when producing cement is to keep the grinding bed stable. In comparison to raw material grinding, with cement milling there are more fines and some parts of the grinding bed tend to become partly fluidised, caused by entrapped air. This reduces the internal friction within the material layer making it difficult to efficiently apply the grinding forces. So the roller removes the air from the grinding bed and prepares the material for the master roller to carry out the grinding. The flowsheet for grinding system with VRM (see Figure shows that, after the classifier, product is precipitated and then recovered from the bag filter. system fan provides the draft through the machine and different sources of hot gases can be utilized if required. Furthermore wide range of feed materials are tolerated and conveyed to the mill via the feeding system. Ambuja Cements Dadri and Nalagarh grinding stations In 2, Loesche received an enquiry for two grinding stations in India. Both would have cement capacity of 1.6Mta and each would be supplied with Loesche VRM with 2tph of grinding capacity. The Dadri project is situated near New Del| Model Type | Bevel-helical gear reducer B2 |

|---|---|

| Gear Type | Bevel Helical Gear |

| Weight (kg) | 1400.000000 |

| Ratio Range | 1 : 7.1…20 |

| Low Speed Output | Solid shaft without parallel key |

| Nominal Torque | 230000 Nm |

| Mounting Arrangements | Horizontal mounting position |

| Manufacturer | Siemens Flender |

| Country of Manufacture | China |

| Data Sheet & Drawings | B2-CH18-B peed shaft LSS gear unit sizes to Technical spec Bevel-helical gear reducer B2 |